Liner is no doubt one of the leading Italian companies in the production of pizza boxes.

Liner Italia has been producing pizza boxes for over 35 years, always offering new ideas for achieving high and satisfactory levels of quality and purity. The company already has state-of-the-art machines, among which a corrugating machine for the production of high quality corrugated board for the food market. With the expansion of Ceriano Laghetto’s new production site, Liner is continuing its investment policy with the purchase of some of the latest generation converting lines. Experience in corrugated cardboard production always involves the use of new technologies that require more and more professionalism and expertise, orienting the company towards a continuous investment in first class technologies.

The pizza market requires technologies that guarantee very high productivity, fast job change and user friendly solutions to facilitate production staff. On the other hand, the quality of flexo printing in pizza boxes is becoming increasingly demanding and the pizza box is more and more becoming a marketing tool.

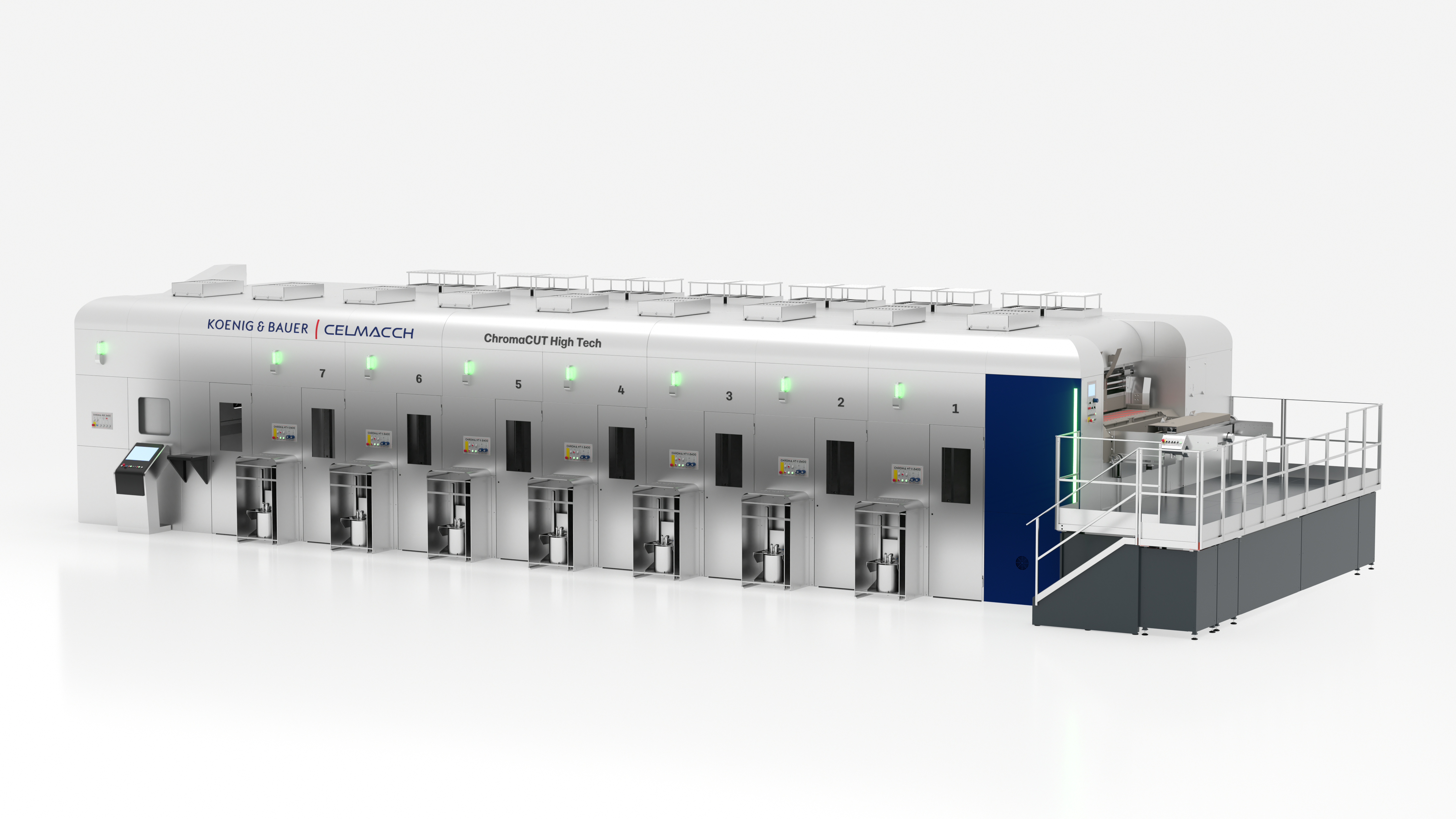

Liner relied on Celmacch in the flexographic printing and at the end of June 2017 installed a new 4-color Chroma Evo 1700 x 1300 mm.

The machine offers the ultimate generation Siemens direct-engine technology, and the bottom printing HBL configuration powers an Eterna flat bed die cutter. Each shaft is powered by a Siemens direct motor. The vacuum transport ensures high precision and perfect accompaniment of the sheet to the flat bed die cutter as well as of course accuracy and perfect print register. Carbon chambered doctor blade system and peristaltic pump provide effective and rapid wash up process as well as the ability to reduce water consumption and ink loss.

The machine is able to reach a maximum speed of 9000 sheets per hour and feeds an existing automatic flat bed die cutter supplied by Eterna. Between the Chroma Evo print and the die cutter there is a vacuum transfer equipped with ejector to allow the operator to eject the sheets to check their quality. Chroma Evo will definitely support Liner in offering its customers a high quality product, in a market that asks for increasingly demanding and high-quality production standards.

Once again Celmacch proves to be the preferred partner of leading industry companies.